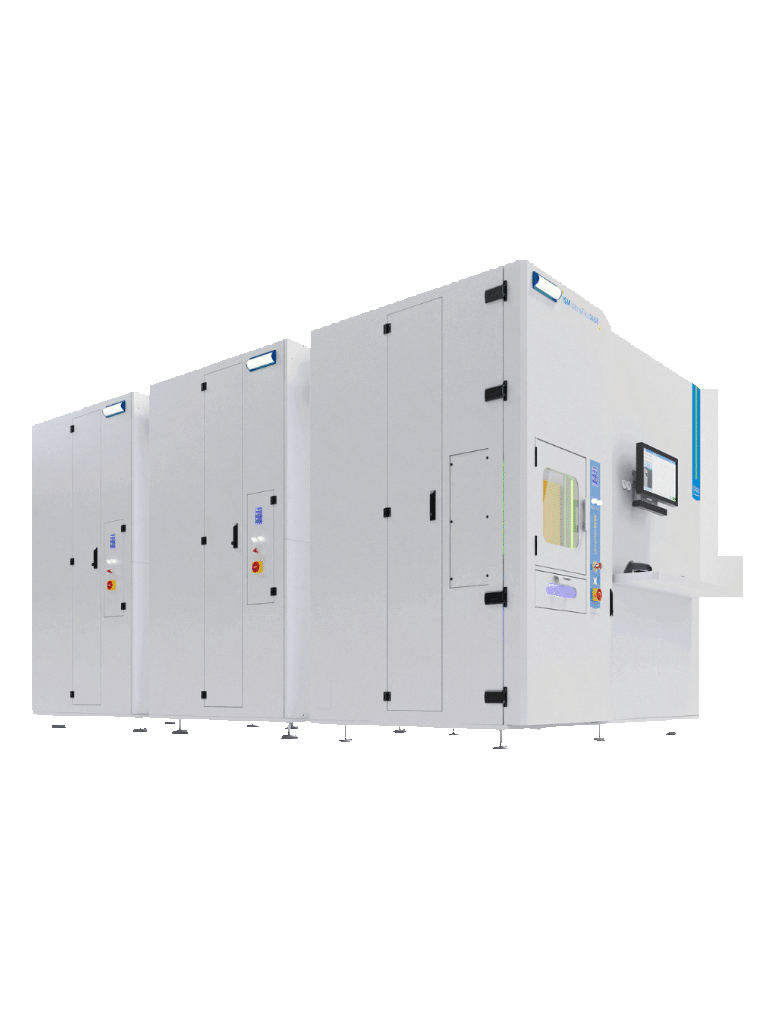

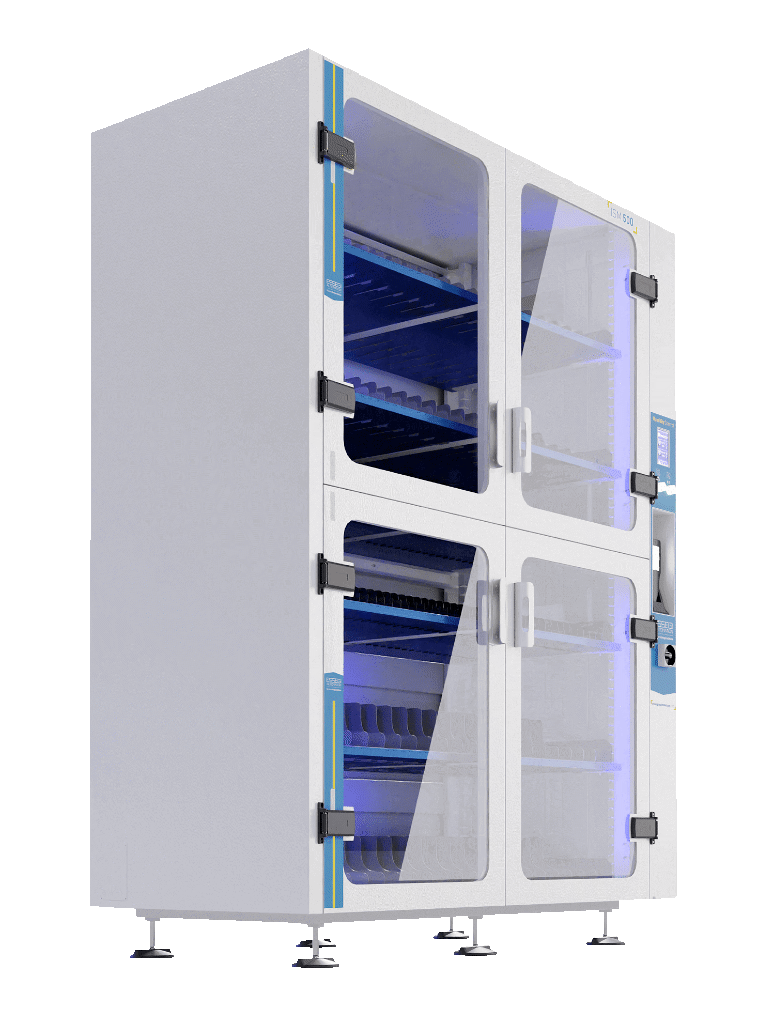

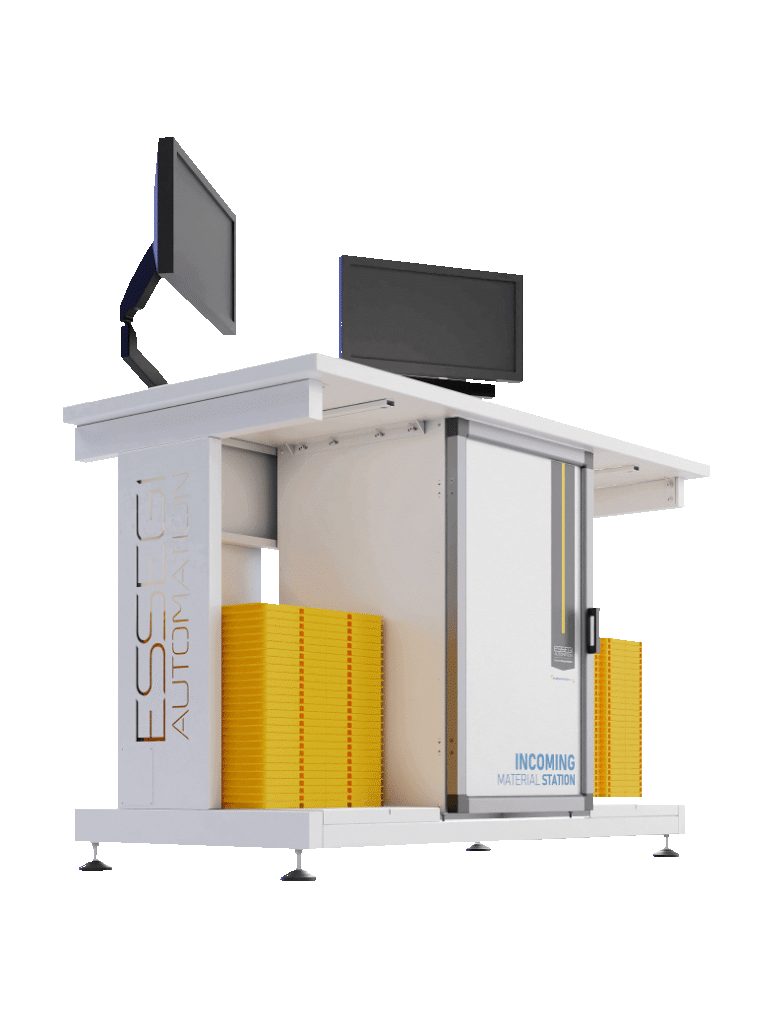

Essegi Automation storage management solutions consists of modular hardware and software products that allow the creation of flexible and open systems capable of communicating with all the main management software and of integrating perfectly into any SMT and THT context.